Specification

Specifying glass block flooring

At concept or feasibility stage there are a number of items to review before the specification or detailing process can begin. Initial questions to ask are:

- Will the elements be subject only to pedestrian traffic or vehicular loads?

- What loading requirements should the panels achieve regarding dead load, live load, point load and super-imposed load?

- Is the precast and glass required to have a fire rating? What fire integrity and thermal isolation rating is required?

- What is the opening size and have you incorporaed expansion joints?

- What type of bearing, perimeter frame and intermediate support do you need?

Most building regulations will require glass block flooring to achieve a minimum of 5Kn per square metre. Precast strength is achieved based on various factors:

- Block type, joint, border width and thickness

- Quantity and gauge of steel reinforcement used

- Panel size

- How many sides the panel is supported on

- Length of any unsupported span

The panel should be designed around the perimeter opening dimensions. Once panels are poured they cannot be altered, added to or cut, so planning the opening size and preparing the bearing is critical.

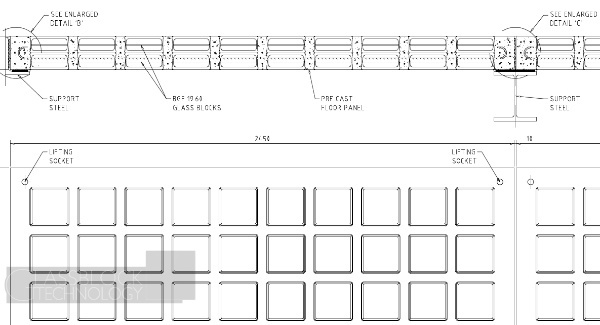

Characteristics of a precast glass block flooring panel

Panels are formed in special moulds and vibrated at high frequency before being left to cure. Curing to full strength will take between three and four weeks.

Floor panels are generally cast the same thickness as the blocks being used. Paviours are 60 or 80mm thick, blocks are 80 or 100mm deep and the BGF1960 fire glass block is 160mm thick.

The panel size is determined by the loading requirement and what bearing is provided to support the panel. These factors determine the blocks/paviours and possible panel thickness and whether slabs can be cast as one element or several.

If the panel depth is required to be thicker, either to suit site conditions or achieve a higher loading, a deeper border can be introduced. With increased depth a ribbing system can be used underneath the joints. This is referred to as a waffle panel.

When using lenses which are 20–22mm thick the waffle is used, otherwise the panel would be too thin to achieve full strength or loading requirements.

Downloads

glass block flooring & precast introduction

glass block flooring & precast introduction Precast Glass Block Flooring

Precast Glass Block Flooring glass block flooring precast specifying & loadings.pdf

glass block flooring precast specifying & loadings.pdf glass block flooring precast fire rating & installation

glass block flooring precast fire rating & installation GBT110 Precast Concrete Floor Panel Sheet 1 of 2

GBT110 Precast Concrete Floor Panel Sheet 1 of 2